Shredding equipment plays an indispensable role in modern recycling and waste management systems. By breaking down tough, bulky materials into smaller, more manageable fragments, industrial shredders make it possible to efficiently sort, bale, transport, and ultimately repurpose a wide range of materials. Read More.....

Vecoplan, LLC open_in_new

Location: Greensboro, NC

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

SSI Shredding Systems, Inc. open_in_new

Location: Wilsonville, OR

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions. Our innovative engineering means equipment for all needs: waste (including medical), metal, paper, tire, e-scrap, plastics, product/security destruction, construction and demolition (C and D).

Granutech-Saturn Systems open_in_new

Location: Grand Prairie, TX

Our long established Saturn-brand industrial shredders are designed with cost and innovation in mind, and provide the benefit you need no matter what you need to shred! Our one-two and four shaft Saturn-Brand shredders can handle metal, plastic, tires, paper, and even automobiles! We can destroy and repurpose nearly any material that you have in your factory. Find out more by visiting www.granutech.com and view our shredder PRODUCT or APPLICATIONS page, or by calling us today.

Williams Patent Crusher & Pulverizer Co. open_in_new

Location: St. Louis, MO

At Williams Patent Crusher & Pulverizer Co., we are a leading manufacturer specializing in the design and production of industrial shredders, crushers, and pulverizers. Our commitment to providing efficient, high-quality machinery is backed by decades of expertise in the industry.

Without this critical stage in the recycling process, many materials would remain too large, too heavy, or too difficult to handle, dramatically slowing recovery operations and increasing landfill waste.

Today’s shredding machines are designed to handle nearly every material type imaginable—rubber, plastics, metals, textiles, wood, paper, cardboard, and more. They are found in municipal recycling centers, manufacturing plants, scrap yards, and specialized processing facilities. By converting oversized or irregular items into uniform pieces, shredders not only simplify downstream processing but also help meet strict material size specifications for secondary manufacturing.

Because of the diverse range of materials they are tasked with processing, shredders come in many designs, sizes, and power capacities. A machine engineered for paper document destruction will be far less heavy-duty than an industrial metal shredder designed for processing automotive scrap or structural steel. Likewise, tire shredders, e-waste shredders, and wood chippers each have specialized features tailored to the challenges of their respective materials.

One application that has seen notable growth in recent years is electronic scrap processing. With the proliferation of consumer electronics—and the rapid obsolescence of many devices—recycling facilities are now tasked with processing vast amounts of old computers, smartphones, televisions, and appliances. Specialized e-waste shredders break down these items to recover valuable metals like copper, aluminum, and gold, while also safely handling plastics, glass, and hazardous materials contained within components such as batteries and circuit boards. This process not only supports environmental sustainability but also aligns with regulatory requirements for responsible electronics disposal.

Heavy-duty industrial shredders are also increasingly vital in tire recycling operations. Tires are dense, bulky, and built to withstand extreme wear, which makes them difficult to process without powerful multi-shaft shredders equipped with hardened steel cutting teeth. By breaking tires down into smaller chunks, these machines enable the production of crumb rubber for use in playground surfaces, athletic fields, and asphalt modification, among other applications.

How Shredders Work

Although shredders vary greatly in appearance and configuration, most operate using the same basic mechanical principles. At the core of the design is a series of interlocking metal shafts, each fitted with a series of cutting discs or blades along their length. These shafts are typically located at the bottom of a hopper or feed chute where materials are loaded.

Once powered by an electric or hydraulic motor, the shafts rotate in opposite directions, creating a powerful shearing action. The discs have sharp, protruding teeth that grip incoming materials, pulling them down between the shafts. As the material passes through, it is torn, sheared, and crushed into smaller pieces. The size of these pieces depends on the spacing of the blades, the design of the teeth, and the number of shafts.

After shredding, the processed material drops into a bin, conveyor, or directly onto the facility floor for collection. From there, it may be cleaned, sorted further, baled, or sent directly to manufacturing plants for reuse. In automated facilities, shredded material often moves seamlessly to the next stage of the recycling process—such as granulating, compacting, or pelletizing—ensuring a continuous workflow.

The choice of drive system also impacts performance. While smaller shredders for light-duty applications often use electric motors for consistent torque and low maintenance, large-scale industrial waste shredders may rely on hydraulic systems to deliver the immense power required to process dense, high-volume loads.

Industrial Shredder Configurations and Applications

Shredders can be configured with different shaft arrangements to meet specific processing needs. A single-shaft shredder is typically used for light-duty tasks, such as processing plastic film, soft metals, or certain packaging materials. These machines are valued for their compact footprint and ability to produce uniform particle sizes.

For heavier applications, dual-shaft shredders are the most common. They use two counter-rotating shafts to deliver greater torque and throughput, making them ideal for large items like pallets, pipes, and certain metals. Many tire shredders fall into this category.

For the heaviest-duty tasks, such as processing massive industrial waste streams, bulky appliances, or construction and demolition debris, three-shaft and four-shaft shredders offer unmatched efficiency. These designs allow material to be processed in stages, improving throughput and ensuring uniform particle sizing even with irregular feedstock.

Selecting the right shredder depends on several factors:

- Material type and density – Metals, rubber, wood, and plastics each have unique shredding requirements.

- Desired particle size – The smaller the end product, the more aggressive the shredding action required.

- Volume and throughput – High-capacity facilities require shredders capable of continuous, heavy-duty operation.

- Maintenance and durability – Hardened steel blades, replaceable wear parts, and robust frame construction extend machine life.

Benefits of Using Shredding Equipment in Recycling

The benefits of incorporating shredding equipment into recycling operations are far-reaching:

- Efficiency Gains – Breaking down materials early in the process increases processing speed, reduces handling complexity, and allows for more efficient transport.

- Cost Savings – Smaller, uniform materials take up less storage space and reduce transportation costs per ton.

- Material Recovery – Shredders enable the separation and extraction of valuable materials, increasing recovery rates and profitability.

- Environmental Impact Reduction – By making recycling more practical and scalable, shredders help divert significant volumes of waste from landfills.

- Regulatory Compliance – In industries such as electronics and medical waste, shredding ensures compliance with destruction and disposal regulations.

Without shredders, it would be logistically and economically challenging to recycle many of the materials we take for granted today. For example, large metal appliances, end-of-life vehicles, or reinforced concrete components would require excessive manual dismantling without mechanical shredding equipment.

Industry Trends and Future Outlook

As sustainability initiatives and circular economy principles continue to shape manufacturing and waste management practices, shredding equipment is evolving to meet higher efficiency and environmental standards. Trends include:

- Automation and Smart Controls – Advanced monitoring systems can detect jams, adjust speed, and optimize energy usage in real time.

- Hybrid and Electric Drive Systems – Reducing the carbon footprint of shredding operations.

- Material-Specific Designs – Custom shredders built for niche markets such as wind turbine blade recycling or lithium-ion battery processing.

- Noise and Dust Reduction – Improved enclosures and filtration systems to meet stricter environmental health and safety regulations.

For businesses evaluating shredding solutions, it’s worth considering not only current material volumes but also projected future needs. As new waste streams emerge and recycling technology advances, investing in a versatile, upgradeable shredder can yield long-term savings and operational flexibility.

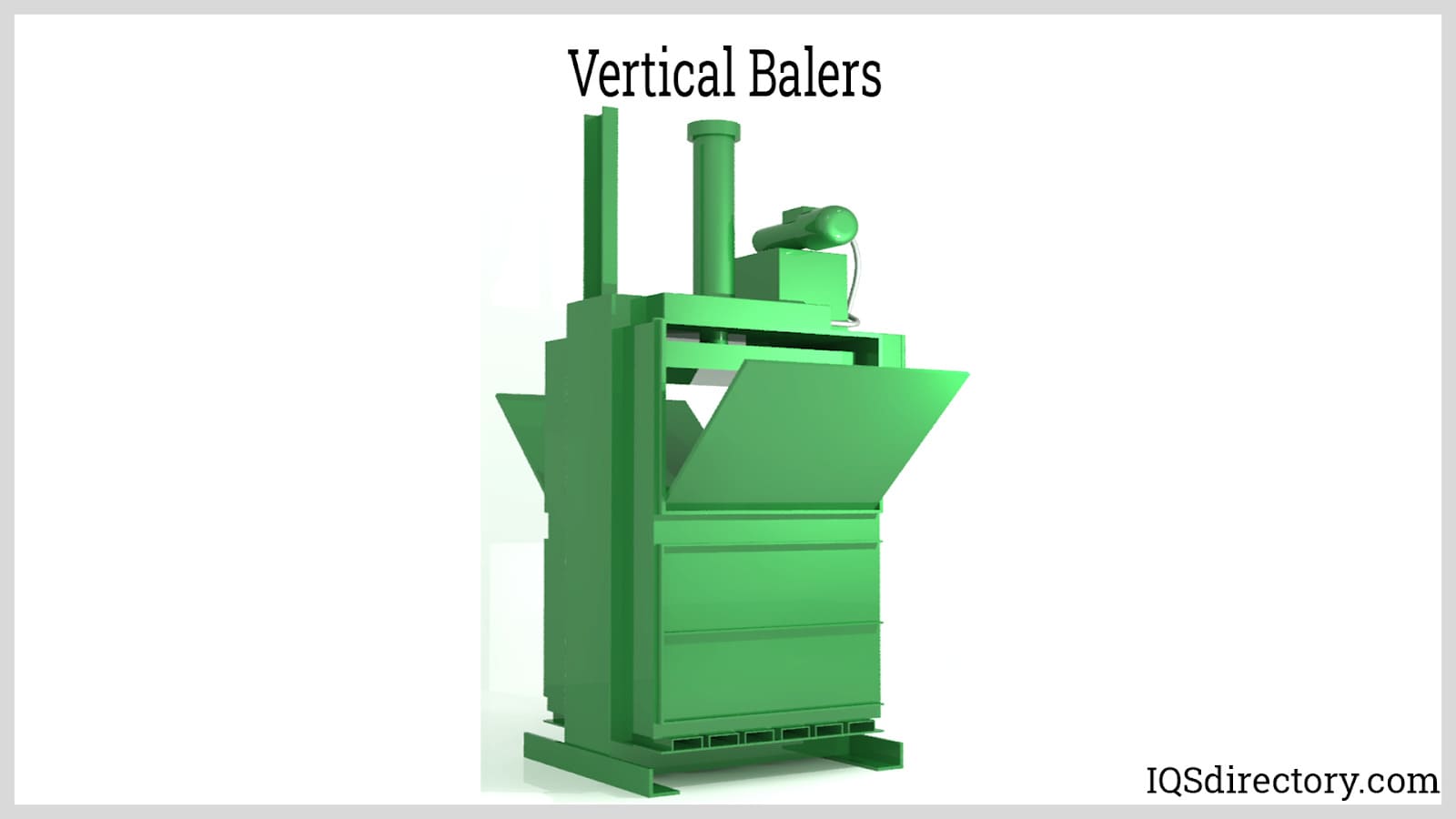

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services