A growing need in manufacturing is the preservation of the environment by making use of waste materials. As sustainability becomes a critical consideration for both consumers and regulatory agencies, every industry is finding ways to be eco-friendly, from reducing emissions to minimizing landfill contributions. Read More.....

Rodix, Inc. open_in_new

Location: Rockford, IL

Rodix manufactures vibratory feeder controls, inline track drives, drive bases, & bulk storage hoppers for part feeding systems. Our line of vibratory feeder controls feature variable amplitude, variable frequency, line-voltage compensation, UL/cUL Listed, CE Marked, and more. We have experience working with machine integrators, vibratory feed system builders, and manufacturers.

PPM Technologies Holdings, LLC open_in_new

Location: Newberg, OR

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

JVI Vibratory Equipment open_in_new

Location: Houston, TX

JVI Vibratory Equipment is a leading provider of vibratory process solutions. JVI manufactures vibratory feeders, screens, spiral elevators, conveyors, & grizzlies – all custom designed and manufactured specifically to meet the customer’s exact application requirements. JVI incorporates dry bulk material handling expertise with years of experience to provide innovative, custom machines unsurpassed in quality and performance.

Performance Feeders, Inc. open_in_new

Location: Oldsmar, FL

Vibratory bowl feeders are our specialty! For four decades we have been offering products that are guaranteed to last! Our vibratory bowl feeders come with multiple sound abatement options, standard and custom control packages and many other options for your convenience of choice! Visit our website today or get in touch with our customer service representatives by email or telephone today!

One of the most impactful steps in this process is implementing systems for recycling and reclaiming valuable resources from production waste.

While having repositories for recyclable waste is a good start, it’s only one stage of the recycling chain. The next and equally critical step is to take the filled waste containers and use separation technology to divide the mixed contents into usable batches. In waste reclamation, this task—sorting recyclable from non-recyclable, valuable from valueless—is both necessary and complex. Organized separation turns what might otherwise be landfill-bound refuse into raw materials for manufacturing, creating a closed-loop production system that benefits both the environment and the bottom line.

Preparing Waste for a Separator

The separation journey begins with collection, often handled by waste management companies. These companies transport materials from manufacturing plants, warehouses, and collection points to specialized processing facilities. Waste from paper and clothing industries generally requires a different handling process than the more complicated waste streams of heavy manufacturing.

Light industrial waste—such as shredded paper, cardboard, textiles, and aluminum cans—can often bypass intensive preprocessing because it’s already sorted or homogeneous in composition. These materials are usually sent directly to recyclers for repurposing.

However, waste from heavy manufacturing tells a different story. Here, separation becomes far more intricate due to the wide range of materials involved. Products like automobiles, industrial machinery, appliances, and electronics contain a blend of metals, plastics, glass, and sometimes hazardous elements. Without separation, these items cannot be economically or effectively recycled.

Before such complex items reach the separator, they must be reduced in size. Industrial shredders, armed with massive steel teeth, rip into objects regardless of their shape, size, or density. This process breaks down equipment into small, manageable pieces, ensuring each fragment can pass through separation equipment efficiently.

Once shredded, the resulting mix—a jumble of metals, plastics, glass, and rubber—is ready for the separator stage, where the task becomes sorting this heterogeneous mass into distinct material categories for reuse.

The Separator Process

Within the separator process, the first priority is usually the recovery of ferrous metals such as iron and steel. Shredded metal pieces often contain both ferrous and non-ferrous materials tangled together. While visually daunting, this challenge is overcome through the use of magnetic separation technology.

As the shredded waste moves along a conveyor belt, powerful magnets suspended above pull ferrous metals away from the rest of the material. This step is fast, efficient, and highly reliable, funneling iron-rich scrap to its own collection point for further processing.

Once the ferrous metals are removed, attention shifts to separating the non-ferrous and non-magnetic components. In earlier recycling operations, this stage often relied on manual picking, where workers sorted waste by hand. Although accurate, manual picking is slow, labor-intensive, and costly for large-scale operations. Today, automated systems take center stage, using advanced technologies to handle high-volume sorting with greater speed and consistency.

Modern Separators

Modern separators incorporate an impressive array of technologies designed to extract maximum value from mixed waste streams. For example, eddy current separators use rapidly spinning magnetic fields to repel non-ferrous metals—like aluminum, copper, and brass—pushing them into designated bins. Air classifiers separate materials by density, allowing lighter components to be carried away by airflow while heavier items drop out. Trommel screens and vibratory separators use mesh openings to sort particles by size, and flotation systems separate materials by buoyancy, allowing lighter plastics to float while denser metals sink.

One of the most significant advancements is the introduction of optical sorting technology. These high-tech systems use cameras and sensors to detect materials based on color, shape, or light spectrum reflection. When the targeted material is identified, an air jet or mechanical arm instantly removes it from the conveyor stream. This method is particularly effective for sorting plastics by resin type, glass by color, or paper by grade.

The goal of these advanced systems is clear: to recover as much reusable material as possible while minimizing contamination, thus increasing the value of the recycled output.

The key to any waste management operation is the separation of reusable waste to be transformed into raw materials. This process not only reduces the volume of waste going to landfills but also conserves natural resources, decreases greenhouse gas emissions from virgin material production, and can generate revenue from the sale of recovered materials.

For manufacturing companies, investing in effective separation technology can mean the difference between meeting sustainability goals and falling short of compliance standards. By recovering high-value metals, plastics, and other resources, businesses can offset waste disposal costs, improve operational efficiency, and strengthen their environmental credentials.

Industries such as automotive recycling, electronics dismantling, construction debris recovery, and municipal solid waste processing rely heavily on separators to make recycling economically viable. Each application comes with its own requirements—an automotive recycler may need powerful magnetic and eddy current separators for metal recovery, while a plastics processor might prioritize optical sorters and air classifiers.

Ultimately, the ongoing development of separation technologies ensures that more materials once considered “waste” can find a second life as part of new products, closing the loop in the manufacturing cycle and helping industries worldwide contribute to a more sustainable future.

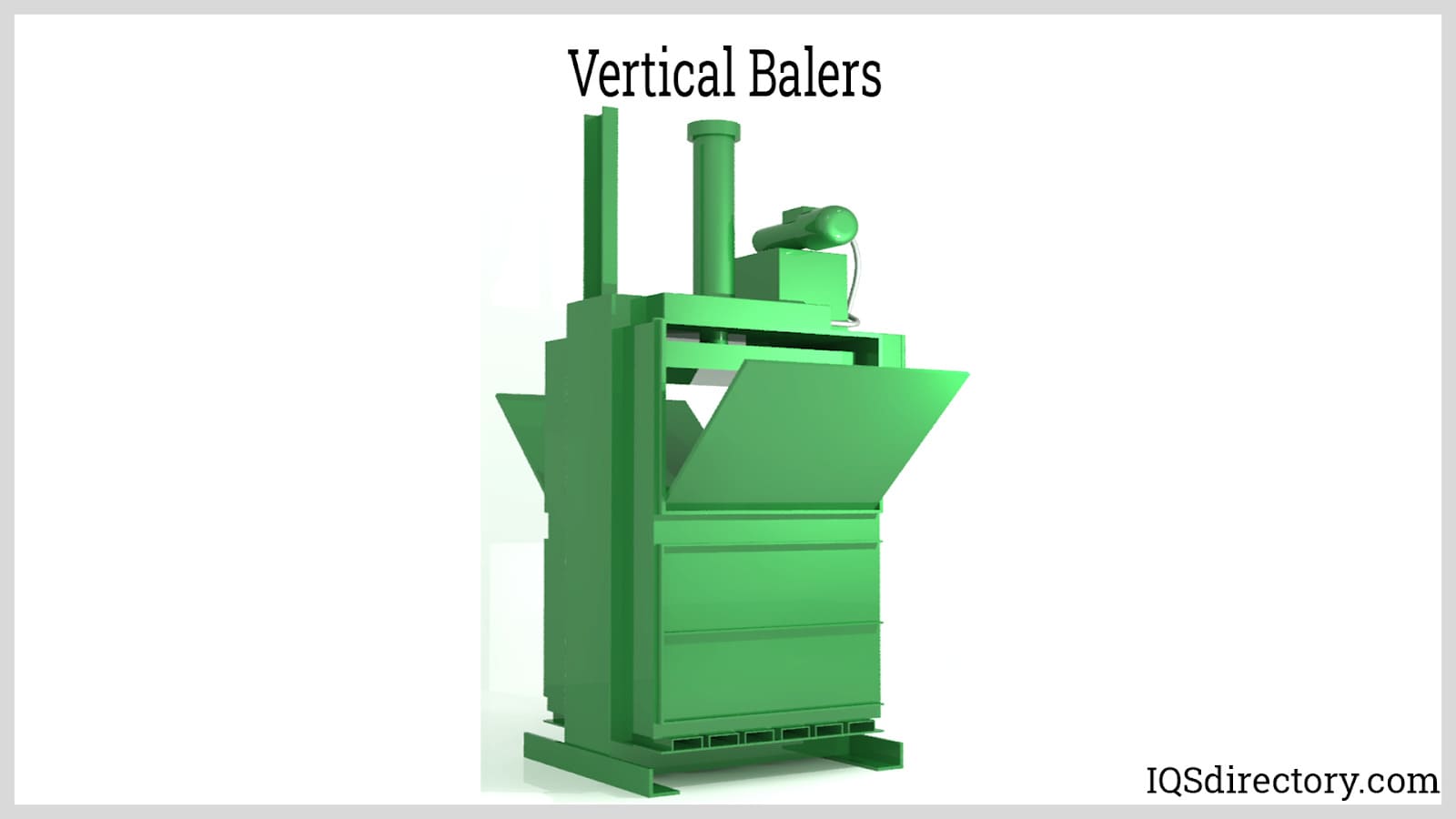

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services