Industrial metal shears are essential cutting machines designed to process large pieces of metal—most commonly sheet metal, steel plates, aluminum panels, and other flat metal stock—into smaller, more manageable sizes. Read More.....

Vecoplan, LLC open_in_new

Location: Greensboro, NC

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

SSI Shredding Systems, Inc. open_in_new

Location: Wilsonville, OR

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions. Our innovative engineering means equipment for all needs: waste (including medical), metal, paper, tire, e-scrap, plastics, product/security destruction, construction and demolition (C and D).

Granutech-Saturn Systems open_in_new

Location: Grand Prairie, TX

Our long established Saturn-brand industrial shredders are designed with cost and innovation in mind, and provide the benefit you need no matter what you need to shred! Our one-two and four shaft Saturn-Brand shredders can handle metal, plastic, tires, paper, and even automobiles! We can destroy and repurpose nearly any material that you have in your factory. Find out more by visiting www.granutech.com and view our shredder PRODUCT or APPLICATIONS page, or by calling us today.

Williams Patent Crusher & Pulverizer Co. open_in_new

Location: St. Louis, MO

At Williams Patent Crusher & Pulverizer Co., we are a leading manufacturer specializing in the design and production of industrial shredders, crushers, and pulverizers. Our commitment to providing efficient, high-quality machinery is backed by decades of expertise in the industry.

These machines play a critical role in metal fabrication, manufacturing, and recycling, allowing facilities to quickly prepare raw materials for production or reclamation. As the sheet metal is fed into the shear, it is sliced into thin strips or smaller sections that can be transported with ease, melted down for reprocessing, or repurposed directly into new products.

How Industrial Metal Shears Work

At the core of a shearing machine’s operation are blades or cutting knives, which exert a powerful force to sever the metal. Depending on the type of shear, this force may be generated manually, mechanically, or hydraulically:

- Manual foot-pedal shears rely on operator strength and leverage, using the downward motion of the pedal to drive the blade.

- Mechanical shears use a motor-driven flywheel to deliver fast, consistent cutting power.

- Hydraulic shears harness pressurized fluid systems to produce high cutting forces with smooth, controlled motion.

Inside the machine, sectional knives or sliding blades are precisely aligned to cut cleanly through the sheet metal. While some cuts are made at a perfect 90-degree angle, many shears are designed with angled blades—a configuration that reduces cutting force requirements and improves efficiency by slicing through the metal diagonally. This not only extends blade life but also minimizes material deformation, which is critical for applications that demand tight tolerances.

Key Components and Feed Process

Metal shears are typically mounted on a shear table—a stable, level work surface that supports the material during feeding. The table allows operators to guide large sheets smoothly into the machine, ensuring accurate alignment and consistent cuts. In stationary shearing setups, the machine remains fixed in place, often as part of a larger production or recycling line. In contrast, mobile shears are mounted on wheels or integrated into heavy equipment, enabling them to be moved across a scrap yard, demolition site, or large industrial facility to cut materials on location.

Some advanced shears include back gauges for precision measuring, squaring arms for aligning edges, and hold-down devices that keep the sheet stable during cutting. These features reduce operator error, increase throughput, and improve cut quality.

Applications in Fabrication and Recycling

Metal shears are a staple in metal fabrication shops, where they are used to cut raw sheet metal to exact specifications for manufacturing parts, components, or structural elements. In many cases, shops source reclaimed sheet metal from suppliers or demolition projects. By trimming and resizing these materials, fabricators can reduce waste and lower costs compared to purchasing new metal stock. This approach supports sustainable manufacturing by keeping reusable materials in circulation.

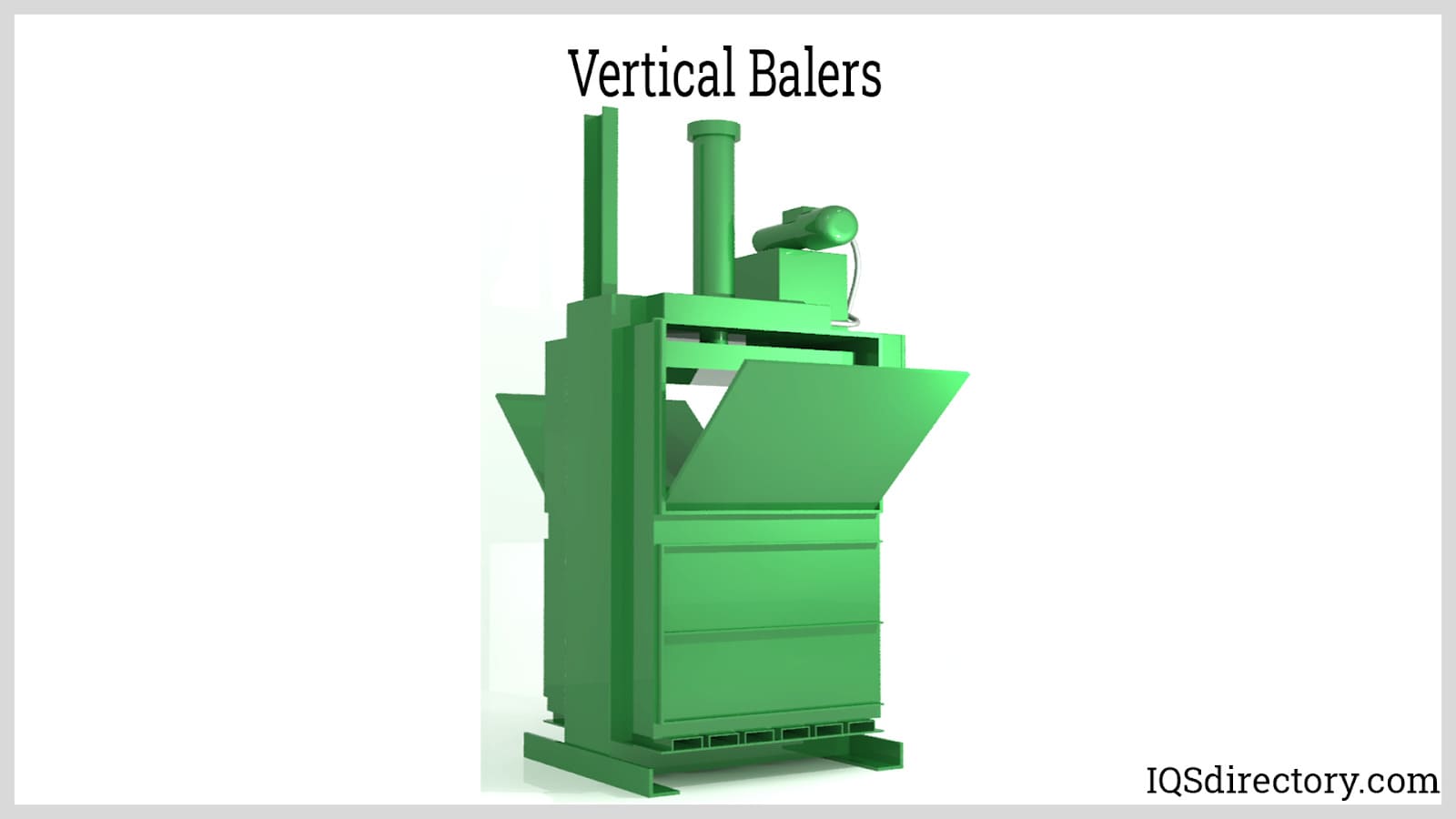

In scrap processing and recycling facilities, metal shears prepare materials for shredding, melting, or baling. Shearing reduces large, unwieldy pieces into uniform sections that are easier to handle and transport. Uniformity is especially important in downstream processes such as industrial baling, where consistent piece sizes improve packing density and shipping efficiency.

Some shearing systems are integrated directly into balers or material recovery systems, allowing continuous processing without the need to transfer materials between machines. This integration boosts throughput and reduces handling time—key advantages for high-volume scrap operations.

Advantages of Using Industrial Metal Shears

- Speed and efficiency: Shears can cut large volumes of material quickly, reducing bottlenecks in production or recycling lines.

- Precision: Advanced shears offer adjustable settings, enabling accurate cuts for parts manufacturing, architectural projects, or structural applications.

- Material versatility: Capable of cutting a range of metals—including carbon steel, stainless steel, aluminum, copper, and brass—in various thicknesses.

- Cost savings: Processing reclaimed or surplus metal reduces reliance on new raw materials, lowering production costs.

- Waste reduction: Shearing produces less scrap compared to other cutting methods, making it more resource-efficient.

- Energy efficiency: Compared to thermal cutting methods like plasma or oxy-fuel, mechanical and hydraulic shearing consume less energy for many applications.

Factors to Consider When Choosing a Metal Shear

For businesses evaluating industrial shear machines—whether for purchase, lease, or integration into an existing system—key decision factors include:

- Cutting capacity: Measured by maximum material thickness and length the shear can handle.

- Blade type and angle: Affects cut quality, required force, and suitability for different materials.

- Power source: Manual, mechanical, or hydraulic—each offers trade-offs in cost, speed, and precision.

- Portability: Whether the operation requires a fixed, in-line machine or a mobile shear for on-site processing.

- Automation features: CNC controls, programmable back gauges, and automatic feeding systems can greatly enhance productivity.

- Maintenance needs: Blade sharpening frequency, hydraulic fluid changes, and general wear-and-tear considerations.

Safety in Shearing Operations

Operating a metal shear requires strict adherence to safety protocols. High cutting forces and sharp blades present hazards, so operators must wear personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots. Machines should be equipped with safety guards, emergency stop controls, and proper lockout/tagout procedures during maintenance. Training is essential to ensure that operators understand load limits, material positioning, and machine controls.

Emerging Trends in Shearing Technology

Advancements in CNC automation, servo-electric drives, and integrated material handling systems are reshaping the metal shearing market. Modern shears can be programmed to perform complex cutting sequences with minimal human intervention, improving consistency and reducing labor costs. Integration with ERP (Enterprise Resource Planning) systems allows real-time tracking of material usage and production output, supporting data-driven decision-making.

Eco-friendly innovations are also on the rise, with energy-efficient hydraulic systems, recyclable lubrication fluids, and low-noise designs that enhance sustainability and workplace comfort.

Shearing in the Circular Economy

The role of industrial shears extends beyond manufacturing—they are critical tools in the circular economy. By enabling the efficient downsizing and repurposing of reclaimed metal, they keep valuable materials out of landfills and reduce the environmental impact of mining and smelting. Facilities that invest in high-quality shearing equipment not only improve operational efficiency but also strengthen their corporate sustainability profiles—a growing consideration for clients, regulators, and investors alike.

Metal Shears Informational Video

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services