In many recycling and recovery plants, scrap and waste materials are stored in large piles before they are processed. These piles can include mixed recyclables such as ferrous and non-ferrous metals, plastics, wood waste, construction debris, paper, cardboard, and demolition byproducts. Read More…

SSI Shredding Systems, Inc. open_in_new

Location: Wilsonville, OR

Tackling the toughest shredding problems since 1980, SSI Shredding Systems designs, manufactures and supports today's most versatile shredders and size reduction solutions. Our innovative engineering means equipment for all needs: waste (including medical), metal, paper, tire, e-scrap, plastics, product/security destruction, construction and demolition (C and D).

Vecoplan, LLC open_in_new

Location: Greensboro, NC

Vecoplan leads the charge with cutting-edge technologies that revolutionize waste and recycling. From versatile shredders and granulators to efficient conveying and sorting systems, Vecoplan offers a wide array of solutions for handling wood, paper, plastics, textiles, and more. Our tailored equipment sets new industry standards, meeting the demands of even the most challenging applications.

Williams Patent Crusher & Pulverizer Co. open_in_new

Location: St. Louis, MO

At Williams Patent Crusher & Pulverizer Co., we are a leading manufacturer specializing in the design and production of industrial shredders, crushers, and pulverizers. Our commitment to providing efficient, high-quality machinery is backed by decades of expertise in the industry.

For facilities that manage high volumes of bulk material, the use of a grappler is often one of the most efficient, safe, and versatile solutions for introducing stored materials into the recycling and recovery process.

Grapplers are designed to pick up large quantities of scrap from these storage piles and place or feed the material into downstream processing equipment such as material separators, industrial shredders, pulverizers, and balers. By enabling fast, consistent loading, grapplers help maintain steady throughput, prevent production bottlenecks, and reduce the reliance on manual labor for heavy lifting tasks.

A grappler is a piece of material handling equipment that can take on many shapes, sizes, and operating mechanisms, but all share the same purpose—picking up and maneuvering substantial amounts of loose or irregular scrap material. In most applications, the grappler is mounted on the boom or articulated arm of mobile heavy machinery, similar to a backhoe, excavator, or purpose-built material handler. This configuration gives the operator maximum reach, the ability to handle uneven terrain, and the flexibility to load directly into conveyors, hoppers, rail cars, or trucks.

One of the most common variations is the claw grappler, which features a series of curved, heavy-duty steel arms that resemble claws. The operator controls the opening and closing of these arms to grip and release loose material, making it ideal for handling bulk loads quickly and safely. Claw grapplers excel at picking up irregularly shaped items such as twisted rebar, crushed appliances, scrap wood, and loose construction debris.

In recycling plants where metal is the primary focus, it is common to replace the claw assembly with a scrap handling magnet. Magnets offer a cleaner, faster solution for picking up ferrous metals without mechanical clamping. This can significantly speed up material recovery while reducing the risk of damage to surrounding equipment or contamination of non-metal streams.

Grapplers can be powered by hydraulic systems, which provide extremely high clamping force for dense materials, or electric actuators, which may be more suitable for lighter-duty tasks and energy-conscious operations. The lifting arms themselves are built to withstand heavy forces and abrasive materials, often featuring reinforced joints, hardened steel components, and wear-resistant coatings.

Many grapplers are available as attachments for existing heavy equipment, allowing operators to switch between different implements depending on the task. This versatility keeps capital equipment costs lower while giving recycling facilities the specialized handling tools they need to process large volumes of material. For facilities with continuous material handling needs, integrated grappling machines—purpose-built vehicles designed for recycling environments—may be the preferred choice. These units often include stability outriggers, elevated operator cabs for better visibility, and optimized hydraulics for faster cycle times.

When properly integrated into a recycling operation, grapplers deliver several advantages:

- Increased operational efficiency by moving larger volumes per cycle.

- Improved worker safety by minimizing manual handling of heavy or sharp debris.

- Lower wear on other machinery, since dedicated grapplers are optimized for high-load material transfer.

- Better control over material flow, which can improve sorting accuracy and recovery rates.

For decision-makers evaluating material handling solutions, factors such as grapple type, clamping force, rotation capability, and compatibility with existing machines should all be considered. Additionally, facilities should account for maintenance requirements, as grapplers operate in harsh conditions and benefit from regular lubrication, hydraulic inspections, and arm wear monitoring.

Scrap Handling Magnets

A scrap handling magnet performs a similar role to a grappler but uses electromagnetic force instead of mechanical arms to lift and move ferrous metals. These magnets are indispensable in metal recovery operations, where speed, efficiency, and precision are essential to separating steel, iron, and other magnetic materials from mixed waste streams.

Scrap handling magnets are typically mounted to the end of a hydraulic arm, material handler boom, or crane via a heavy-duty chain or quick-coupling system. The magnet assembly itself is enclosed in a rugged steel casing designed to protect the coil from impact damage, heat, and environmental wear. While round magnets are the most common, rectangular and custom-shaped designs exist for specialized loading and sorting applications.

When energized, the electromagnetic coil generates a strong magnetic field that attracts ferrous materials from piles or mixed debris. Once lifted and positioned over a designated drop zone—such as a conveyor belt, sorting station, or container—the operator deactivates the current, releasing the load instantly. This process eliminates the need for mechanical gripping, allowing for faster, cleaner, and more controlled handling of metals.

The lifting power of scrap magnets can be substantial, with heavy-duty models capable of moving several tons of metal in a single lift. This makes them ideal for high-throughput facilities such as steel mills, scrapyards, auto dismantling operations, and large-scale recycling plants. They are also highly effective in shipbreaking yards and demolition sites where large metal components must be quickly removed and processed.

Key advantages of scrap handling magnets include:

- High-speed metal recovery with minimal manual sorting.

- Reduced contamination in non-ferrous streams by efficiently separating ferrous content.

- Lower maintenance costs compared to mechanical claws, as there are fewer moving parts subject to wear.

- Versatility in handling everything from small metal fragments to heavy steel beams.

Magnets are available in various diameters, duty cycles, and field strengths, enabling operators to choose models suited to their workload and environment. For example, continuous-duty magnets are designed for non-stop operation in busy scrap yards, while intermittent-duty magnets may be more cost-effective for smaller operations.

Some advanced scrap magnets are paired with generator-equipped material handlers, making them fully self-contained and mobile. This is particularly useful in temporary work sites or remote locations where external power sources are unavailable.

Integrating Grapplers and Magnets for Maximum Efficiency

In many facilities, grapplers and scrap handling magnets are used together to create a comprehensive material handling system. Grapplers excel at handling non-metallic and mixed materials, while magnets specialize in ferrous metal recovery. By combining these tools, operations can achieve higher throughput, reduce downtime, and improve the quality of sorted materials.

A typical setup might use grapplers to load mixed waste into a sorting line, where magnets downstream extract ferrous metals. Alternatively, magnets may be used first to clear metals from a pile, with grapplers then moving the remaining material into shredders or balers.

From an investment standpoint, both tools can increase return on investment (ROI) by reducing labor costs, minimizing material loss, and enabling the resale of recovered metals and recyclables at higher purity grades.

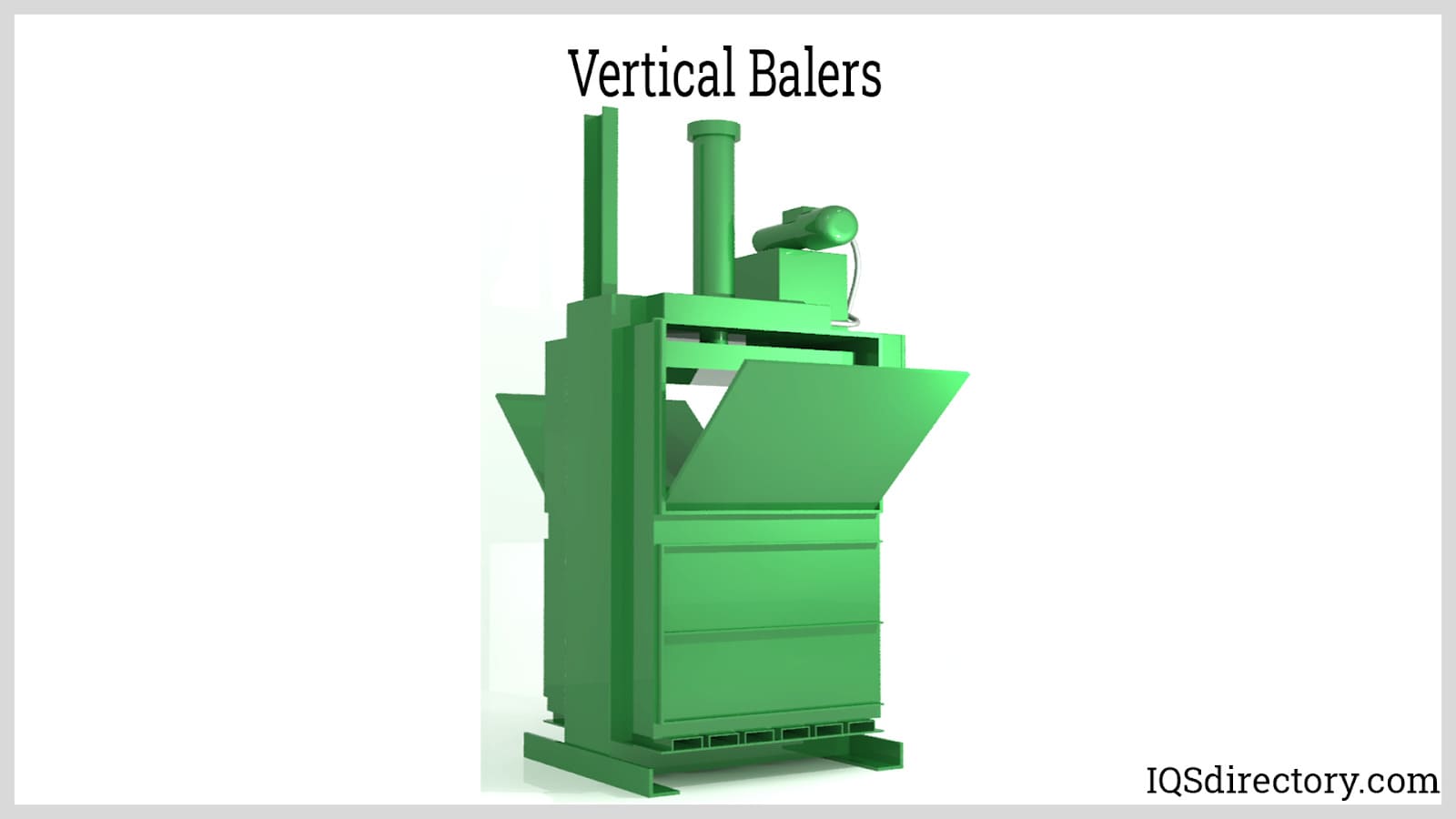

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services