Balers are essential pieces of industrial recycling equipment designed to compress and bind recyclable materials into compact, manageable bales. By pushing materials together under high pressure, balers form dense, block-like shapes that are easy to stack, store, and transport. Read More.....

Maren Balers & Shredders open_in_new

Location: South Holland, IL

Since 1962, Maren has led the industry, building powerful and reliable manual tie, automatic tie and two ram balers, shredders and conveyors. That’s why many of the most successful paper & box plants, distribution centers, post consumer recyclers, and printers rely on Maren Balers to bolster their bottom line. Maren’s reputation for great customer service has carried from generation to generation of operators, service technicians and equipment buyers worldwide.

Excel Baler LLC open_in_new

Location: St. Charles, MN

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

International Baler Corporation open_in_new

Location: Jacksonville, FL

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider our range of industrial compactors and related equipment. We carry a large variety of models. We can even customize a piece of baling equipment to fit a client’s specific needs. You will be surprised at the variety of options that fit your budget.

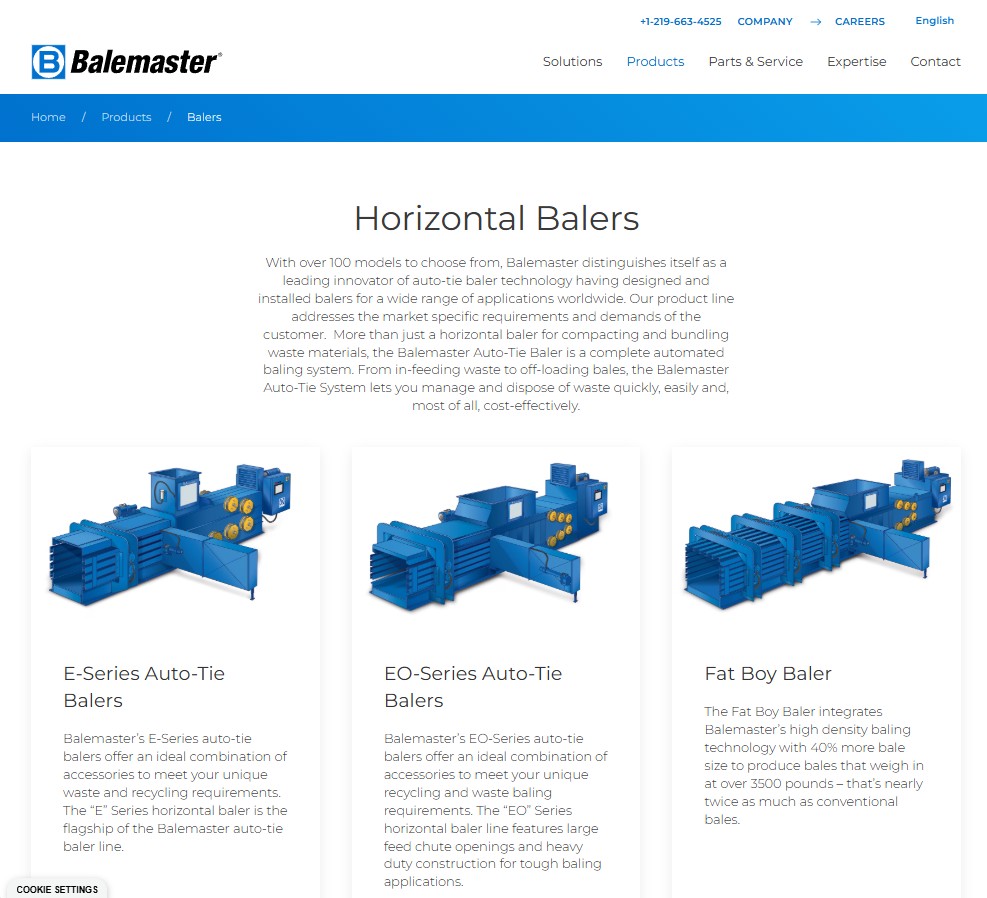

Balemaster® open_in_new

Location: Crown Point, IN

For over 60 years, Balemaster® has distinguished itself as the world's leading manufacturer of heavy duty reliable balers, shredders, hoggers, fluffers & perforators to meet nearly any requirement. We have equipment to meet your exact needs from a broad line of closed-door, auto-tier, wide-mouth & large feed hopper models--built to be the best & backed by flexible service programs.

SSI Shredding Systems, Inc. open_in_new

Location: Wilsonville, OR

SSI Shredding Systems, Inc. has manufactured industry proven shredder solutions globally since 1980. Our shredders are versatile, effective, and ready to be fully integrated into the waste reduction systems already present in your process. We offer a full range of single shaft, two shaft, and four shaft shredders as well as primary reducers and compaction solutions. Contact us today find the right solution today.

This process is critical for waste reduction and materials recovery, allowing recyclers, manufacturers, and waste management companies to optimize space, improve logistics, and reduce transportation costs.

In modern recycling facilities, recovered materials such as cardboard, paper, plastics, textiles, and scrap metals are often sorted and then fed into a baling machine. Once compacted into bales, these materials can be shipped directly to manufacturers for melting, shredding, or reprocessing into new products. By converting loose recyclables into uniform blocks, balers streamline the supply chain from collection to re-manufacturing.

Moisture Extraction for Cleaner Bales

Some advanced hydraulic balers come equipped with moisture extraction systems to remove liquids that may remain in containers before processing. This feature is particularly valuable when baling cardboard, plastics, or metals that have been used for beverages, cleaning products, or other liquid-containing items. Moisture removal not only prevents contamination but also reduces bale weight, making transportation more cost-effective. Dry, residue-free bales are also preferred by manufacturers, as they can be stored longer and processed more efficiently without additional drying steps.

How a Baler Works

The baling process typically begins by loading a high volume of material into the input hopper or feed area of the machine. From there, the material moves into the compression chamber, where a hydraulic ram applies consistent pressure to crush and shape the material into a dense cube or rectangular block. Most industrial balers are electrically powered but rely on hydraulic pressure for compaction, ensuring a powerful and reliable compressive force.

Once compacted, the bale is secured with steel wire ties, plastic strapping, or heavy-duty twine to maintain its shape during handling and transport. Some balers offer adjustable bale sizes, allowing facilities to customize dimensions based on shipping requirements, storage space, or material type. Due to their weight, completed bales are typically moved with forklifts, pallet jacks, or automated conveyor systems and either stored for future processing or loaded directly onto trucks for shipment.

Why Compact Bales Are Essential for Manufacturers

For manufacturers in industries that rely on recycled raw materials, compact bales provide efficiency, consistency, and cost savings. Large volumes of uniform material can be stored on-site until production needs arise, enabling continuous operation without frequent resupply. During high-demand periods, having pre-baled materials on hand ensures smooth production flow and reduces downtime.

Industries such as paper mills, plastic extrusion plants, textile manufacturers, and metal foundries benefit greatly from baled inputs because they can be fed directly into processing equipment with minimal preparation.

Main Types of Industrial Balers

While the function of all balers is similar, different designs are optimized for specific materials, volumes, and facility layouts. The three primary categories are vertical balers, horizontal balers, and two ram balers.

Vertical Balers – Compact and Cost-Effective

A vertical baler uses a vertically oriented ram to compact materials. These machines are loaded through a large front-opening chamber, which is then closed before compaction begins. Their upright design takes up significantly less floor space than horizontal models, making them ideal for small to mid-sized facilities, retail stores, and warehouses where space is at a premium.

Key advantages of vertical balers include:

- Lower initial cost compared to horizontal systems

- Versatility for cardboard, mixed paper, plastics, and textiles

- Simple manual loading and operation

- Compact footprint for tight spaces

Although vertical balers are often associated with cardboard recycling, many models can handle a range of materials, and they can be customized for specific industry needs. For example, grocery stores, distribution centers, and retail chains often use vertical balers to manage cardboard packaging waste efficiently.

Horizontal Balers – High-Volume Material Handling

A horizontal baler uses a side-oriented ram to compress materials. These balers are significantly larger than vertical units and are designed to handle continuous, high-volume material streams. They are often paired with automated feeding systems such as conveyors or mechanical loaders to maintain a constant flow of recyclables into the compression chamber.

Key features of horizontal balers:

- Capable of continuous operation for 24/7 facilities

- Handles larger quantities of material in less time

- Compatible with automated sorting and feeding systems

- Suitable for paper, cardboard, plastics, scrap metal, and more

Because they are more powerful and versatile, horizontal balers are the preferred choice for large-scale recycling plants, manufacturing facilities, and waste transfer stations. Their efficiency reduces labor costs, speeds up processing, and supports higher throughput.

Two Ram Balers – Power for Bulkier Materials

A two ram baler is a type of horizontal baler equipped with two independently operating hydraulic rams. One ram is dedicated to compression, while the second is used for ejecting the completed bale, allowing for faster cycle times and more efficient handling of bulky or dense materials.

Two ram balers are often used when:

- Processing mixed recyclables without prior shredding

- Handling metals, rigid plastics, tires, or large debris

- Producing bales with consistent density and shape for shipping

In some cases, two ram balers can eliminate the need for pre-conditioning processes such as shredding or pulverizing, making them an efficient choice for facilities looking to maximize output while minimizing equipment steps.

Applications of Industrial Balers

Industrial balers are used in a variety of industries beyond just recycling facilities, including:

- Retail & Distribution – Managing cardboard and packaging waste

- Manufacturing – Compacting production scrap and offcuts

- Agriculture – Baling crop residue, hay, and silage

- Waste Management Companies – Sorting and compressing municipal recyclables

- Scrap Metal Processing – Compressing ferrous and non-ferrous metals for transport

Benefits of Using a Baler

Investing in the right baling machine offers multiple benefits:

- Reduced waste volume for lower disposal costs

- Streamlined storage and transportation of recyclables

- Improved workplace safety by reducing loose material hazards

- Increased revenue from selling high-quality, compact bales to recyclers or manufacturers

- Environmental benefits through waste diversion and resource conservation

How to Choose the Right Baler

When selecting a baler, consider:

- Material type – Are you compacting cardboard, plastics, metals, or a combination?

- Volume – Daily or weekly throughput determines machine size and speed

- Space constraints – Vertical balers for small spaces; horizontal for large facilities

- Automation needs – Manual loading vs. conveyor-fed systems

- Budget & ROI – Balers can generate savings by reducing hauling costs and generating recyclable revenue

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services