One of the most urgent challenges facing the modern waste management industry is the diminishing availability of landfill space. Each year, millions of tons of disposable waste are produced worldwide, much of which is destined for burial. Read More.....

Excel Baler LLC open_in_new

Location: St. Charles, MN

The only thing stronger than an Excel baler is the loyalty of our customers. Excel continues to break new ground by designing equipment with energy-saving technologies, developing balers to fit your business and solve your problems, and introducing products that process more material and make you more money. While the competition makes their balers cheaper, we make Excel balers better!

International Baler Corporation open_in_new

Location: Jacksonville, FL

If you are currently paying for the disposal of cardboard, paper, plastic or non-ferrous metals; than consider our range of industrial compactors and related equipment. We carry a large variety of models. We can even customize a piece of baling equipment to fit a client’s specific needs. You will be surprised at the variety of options that fit your budget.

Ely Enterprises, Inc. open_in_new

Location: Lorain, OH

Founded in 1981, Ely Enterprises, Inc. has established itself as a leader in the baler manufacturing industry, specializing in premium baler products essential for effective material handling and waste management. Our balers are designed to maximize efficiency, reduce waste, and help companies optimize their recycling processes, benefiting industries from recycling and manufacturing to waste processing and distribution.

SSI Shredding Systems, Inc. open_in_new

Location: Wilsonville, OR

SSI Shredding Systems, Inc. has manufactured industry proven shredder solutions globally since 1980. Our shredders are versatile, effective, and ready to be fully integrated into the waste reduction systems already present in your process. We offer a full range of single shaft, two shaft, and four shaft shredders as well as primary reducers and compaction solutions. Contact us today find the right solution today.

Despite the adoption of advanced recycling programs, composting initiatives, and sustainable manufacturing processes, landfill sites continue to fill at unprecedented rates. This growing pressure on waste facilities has made it essential for municipalities, businesses, and even households to adopt more efficient waste reduction solutions, with trash compactors emerging as one of the most effective tools for addressing this need.

First introduced in the 1940s, the trash compactor represented a major shift in how communities manage solid waste disposal. A large portion of what fills garbage bins and landfills is not solid matter but air pockets and trapped gases. By applying significant compressive force to waste materials, compactors remove this excess air and compress the contents into dense, manageable forms. This process can reduce several hundred cubic feet of loose material to less than one hundred cubic feet, dramatically improving storage efficiency and decreasing the frequency of waste hauling.

What Is a Trash Compactor?

The term “trash compactor” covers a wide range of devices designed to compress waste by removing unnecessary volume. These machines come in various designs and sizes to suit different applications, from compact residential models that can be tucked neatly under kitchen counters to high-capacity industrial compactors capable of processing tons of waste daily.

Residential compactors, typically holding between 30 and 40 pounds of waste, allow households to reduce the number of garbage bags used and decrease trips to outdoor bins. In commercial and industrial settings, compactors play a central role in reducing operational waste costs and meeting environmental compliance requirements. Many businesses now incorporate compactors into broader sustainability initiatives, pairing them with recycling equipment and waste sorting systems to maximize resource recovery.

Types of Trash Compactors and Industry Applications

The design and capacity of a trash compactor depend heavily on the type of waste generated, the volume of material, and the operational environment.

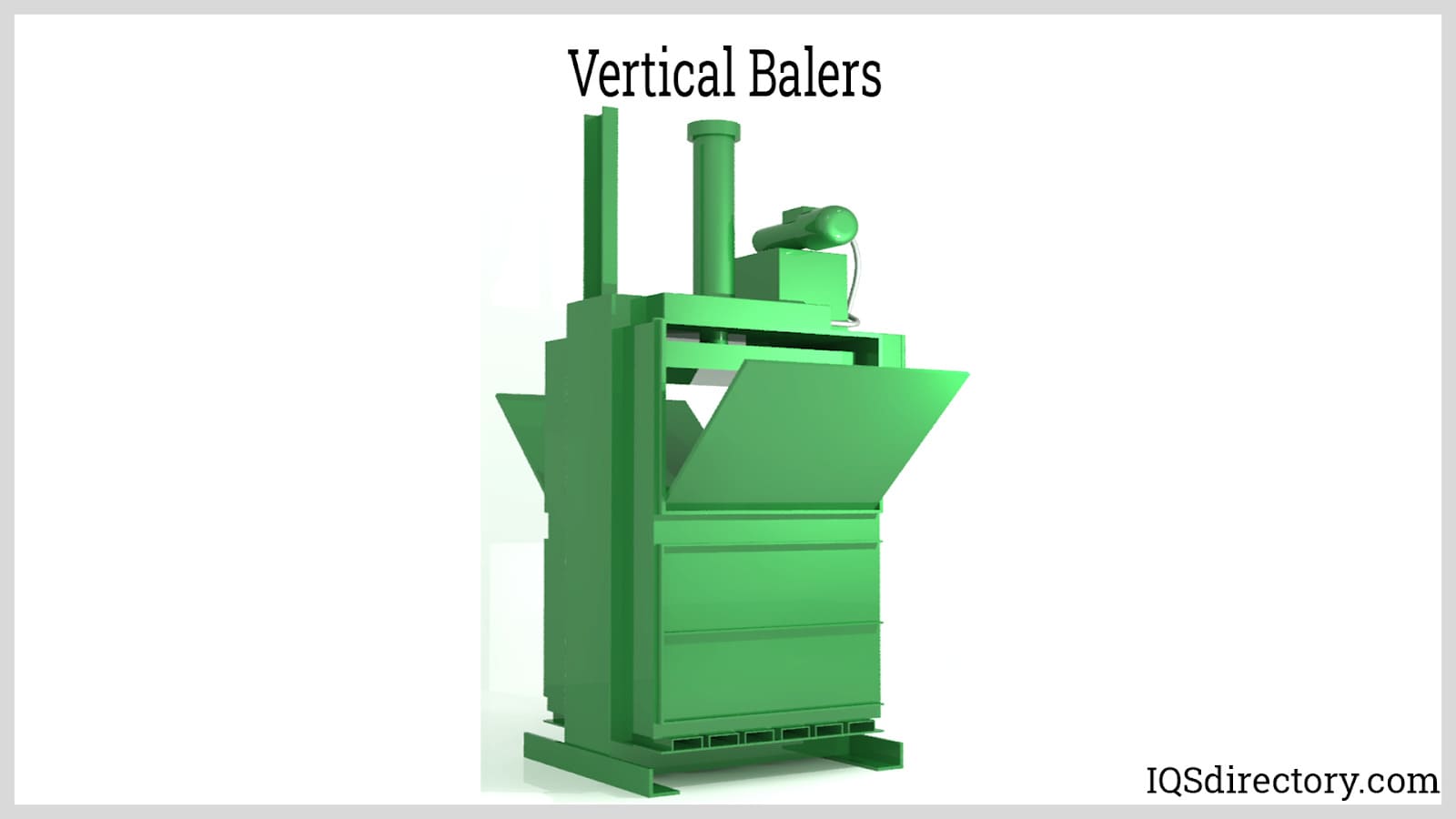

In office and retail environments, smaller vertical compactors are commonly used to handle paper, cardboard, and lightweight packaging waste. They help maintain organized backrooms and loading areas while minimizing pickup frequency from waste haulers.

Manufacturing and industrial facilities rely on heavy-duty horizontal compactors to manage larger, bulkier waste streams, such as wood pallets, metal scraps, plastic sheeting, and production byproducts. Many of these machines can be integrated into automated material handling systems, allowing waste to be fed directly from assembly lines into the compactor without manual loading.

In hospitality, healthcare, and food service industries, specialized compactors are used to handle organic waste, ensuring odor control, improved sanitation, and compliance with local waste disposal regulations. These units often feature sealed chambers, drainage systems, and antimicrobial coatings to manage liquid content and prevent contamination.

Across all sectors, the right compactor reduces waste volume, lowers hauling expenses, and supports compliance with environmental management standards. Businesses choosing a compactor typically consider waste type, daily throughput, available floor space, energy efficiency, maintenance requirements, and safety features.

How Trash Compactors Work

At the core of a trash compactor is the ram—a hardened steel plate designed to exert extreme pressure on the waste material. Depending on the model, the ram can be mounted in a vertical or horizontal position and is guided along precision tracks to ensure stability and alignment. The ram is powered by a hydraulic or pneumatic piston, capable of generating enough force to compress waste into a uniform cube or rectangular bale.

When waste enters the chamber, the ram advances to apply direct pressure, forcing the material into its smallest possible volume. The minimal clearance between the ram and chamber walls prevents debris from escaping during the compression cycle. In industrial units, this process is often automated, with conveyor belts or chute systems feeding waste directly into the compactor from production areas.

Regular maintenance is essential to ensure smooth operation. Ram tracks, guide rails, and hydraulic systems require routine inspection and lubrication to maintain optimal performance. Preventative care not only extends equipment lifespan but also helps preserve compaction efficiency over time.

Sizes and Configurations for Different Needs

The size of a trash compactor is determined not just by waste volume but also by the specific demands of the facility.

For small offices and local businesses, compact vertical units are sufficient for reducing paper, cardboard, and light packaging waste. They are easy to install, require minimal training, and provide a straightforward way to lower waste collection frequency.

For large-scale operations such as manufacturing plants, warehouses, and distribution centers, horizontal compactors or stationary compactors with roll-off containers are the preferred choice. These units can handle continuous loading and are designed for materials with higher density or irregular shapes.

Special attention is required when compacting materials with unique handling requirements, such as avoiding flammable, volatile, or hazardous substances. In these cases, facilities often use specialized waste management systems that separate dangerous materials before compaction.

Loading, Emptying, and Operational Efficiency

In residential and small commercial models, waste is manually loaded and compacted at the push of a button. These units are emptied by removing an internal bin or bag.

In industrial environments, the process is more complex and efficiency-driven. Compactors are loaded automatically through integration with production lines or material handling systems. When the unit reaches capacity, the entire container is detached and replaced, often multiple times per day in high-output facilities. This minimizes downtime and ensures that waste handling does not disrupt core operations.

Automated compactors often come equipped with features such as safety interlocks, bin-full indicators, and programmable compaction cycles, which further enhance productivity while maintaining operator safety.

Environmental and Economic Benefits

The adoption of trash compactors offers measurable advantages for both environmental sustainability and cost control. By reducing the volume of waste, compactors lower the number of trips required for collection, which translates into fuel savings and reduced greenhouse gas emissions from hauling trucks. Compacting also helps businesses meet sustainability targets by decreasing landfill contributions and improving recycling rates through better material separation.

From an economic standpoint, compactors reduce waste hauling fees, free up valuable floor or storage space, and enhance workplace cleanliness. Over time, these savings can offset the initial investment in equipment.

As waste disposal regulations become increasingly strict and landfill tipping fees rise, the long-term financial and operational value of compactors continues to grow. Many organizations now view them not just as equipment purchases but as strategic investments in environmental responsibility.

The Future of Compactors in Waste Management

With global waste generation on the rise and landfill space at a premium, the role of trash compactors in waste management will only become more critical. Advancements in compactor technology are introducing energy-efficient drives, smart monitoring systems, and IoT integration, allowing facilities to track usage, monitor fill levels in real time, and schedule pickups more efficiently.

In the years ahead, compactors will likely be paired more closely with automated recycling systems, AI-driven sorting technologies, and sustainable waste-to-energy solutions. For industries committed to reducing their environmental footprint while controlling costs, these machines will remain an essential part of the waste management toolkit.

By optimizing space, improving sanitation, and supporting compliance with environmental regulations, trash compactors continue to prove their value as one of the most effective tools in the fight against waste overproduction and landfill overcrowding.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services