A vibratory feeder, also known as a vibratory conveyor, is a type of equipment that uses vibrations to transport bulk material through stages of a particular process, like packaging, recycling, or finishing. Vibratory conveying differs from standard belt, screw, and pneumatic conveying in that it can handle sticky or delicate materials without damaging them or causing them to liquefy. Read More.....

Eriez open_in_new

Location: Erie, PA

ERIEZ is a global manufacturer of an entire range of vibratory feeders and related machinery. We serve all the process industries, including food, chemical, pharmaceutical, ceramics, glass, packaging, metalworking, minerals processing and others. We also offer feeding machines so that all of your needs can be met. Please contact our company for a quote today!

Rodix, Inc. open_in_new

Location: Rockford, IL

Rodix manufactures vibratory feeder controls, inline track drives, drive bases, & bulk storage hoppers for part feeding systems. Our line of vibratory feeder controls feature variable amplitude, variable frequency, line-voltage compensation, UL/cUL Listed, CE Marked, and more. We have experience working with machine integrators, vibratory feed system builders, and manufacturers.

PPM Technologies Holdings, LLC open_in_new

Location: Newberg, OR

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

United Toolers of IL open_in_new

Location: Loves Park, IL

At United Toolers of IL, we take pride in our expertise in designing and manufacturing vibratory feeders that deliver precision and efficiency to a wide range of industries. Our vibratory feeders are engineered to provide seamless part handling, ensuring optimal flow and positioning for automated production lines. We focus on creating solutions that meet the specific needs of our clients, whether they require gentle part orientation, high-speed handling, or custom configurations.

Jerhen-Warren Industries, Inc. open_in_new

Location: Rockford, IL

At Jerhen-Warren Industries, Inc., we specialize in designing and manufacturing advanced vibratory feeders that ensure smooth, efficient material handling for diverse applications. Our expertise spans the full spectrum of vibratory feeding systems, where we integrate innovative technology and precise engineering to develop reliable solutions tailored to our clients' operational needs.

Vibratory feeders are ideal machines to use for material handling as they are low-maintenance, and the only moving part it contains is a vibrating drive located underneath the feeder pan and out of the way of any materials. The other parts of a vibratory feeder are inexpensive and easy to replace.

Vibratory feeders can be powered either electromagnetically or electromechanically, the latter of which is driven by a motor supported by eccentric weights or an eccentric crank.

There are several main types of vibratory feeders. The first, vibratory bowl feeders, are also referred to as centrifugal feeders or vibratory bowls. These feeders are used by parts manufacturers to align finished or semi-finished parts to prepare them for packaging. The second, vibratory conveyors, covers a broader range of troughs, trommel screens, and vibrating screens that are made for the purpose of conveying and sorting bulk materials. The third, rotary feeders, are also referred to as rotary valves or rotary airlocks. They transfer airtight bulk material to vibratory or screw conveyors. The fourth and final category is linear feeders, or inline feeders, which are commonly used to transport parts from bowl feeders in a vibratory linear motion for short or relatively long distances.

Small parts manufacturers use vibratory bowl feeders extensively for the purpose of efficiently orienting products for distribution or further finishing. Bowl feeders were originally designed by pharmaceutical companies to sort, count, and organize pills. Nowadays, they are also built to work with items such as toothpaste caps, molded rubber parts, o-rings, ammunition, and fasteners.

Many industries—such as food processing, agricultural, and pharmaceutical—use vibratory conveyors, screens, and trommels for bulk and powder material handling. Vibratory conveyors are used frequently in recycling industries to sort and convey numerous materials such as metals, crushed cement, wood, and plastic. Mining, pulp, sand and gravel, and fertilizer companies use vibrating screens and trommel screens to sort, sift, and convey their materials. A grizzly screen is a powerful type of vibrating screen which is most frequently used in the mining industry. Vibratory conveyor systems usually work together with rotary airlock feeders when they must convey powder bulk solids. In the processes of reclamation or collecting dust, rotary feeders and dust collecting systems are used together.

Bowl feeders are similar to vibratory finishing bowls, and are made of plastic, silicone, or metal. These machines are equipped with a vibrating drive that is mounted to the bowl’s base. A ramped ridge—which is typically designed for a specific part—leads to the outfeed area, and runs up along the bowl’s edge in a spiral. The bowl, which vibrates in a circular motion, moves the parts up the spiral ridge. As it reaches the output area, it narrows and forces the parts to form a single-file line. Small parts such as coins, legos, o-rings, and washers can easily be aligned for packaging and counting when they are dumped into the bowl feeder’s center.

Vibratory conveyors vibrate in one direction, and they move heterogenous mixtures or powder bulk solids from one piece of equipment to the next. Some varieties of these vibratory conveyors have ultra-low vibrations for the purpose of handling solids such as lettuce or gummy bears which are sticky, delicate, or prone to liquefy.

Trommels, or trommel screens, are vibrating screens which separate small and large particles. Rotary trommels are used in recycling and the processing of gravel. Trommel magnets help sort ferrous from non-ferrous materials, and are frequently used alongside metal recycling rotary trommels. Continuous flatbed trommels usually have filtering devices or screens that help in sorting particles of varying sizes. Larger particles are conveyed either to be further processed or contained.

The incorporation of vibratory feeders into various industrial processes has many benefits. Feeders are highly cost-effective in comparison to manual labor, and therefore can save a company more time and money in labor costs. Instead of one operator per machine, a number of automated machines can be overseen by one operator. Bowl feeders can process small parts more accurately, quickly, and effectively than a worker can do by hand. In addition to saving time and money, it also spares workers strenuous and tedious tasks. Vibratory conveyors are an alternative solution for machines such as belt, screw, or pneumatic conveying, as vibratory conveyors are more capable of handling sticky or friable materials that would otherwise be more likely to agglomerate or cake. Trommel screens and rotary trommels are more capable of efficiently sorting recyclable materials by reducing the labor required to carry out the process.

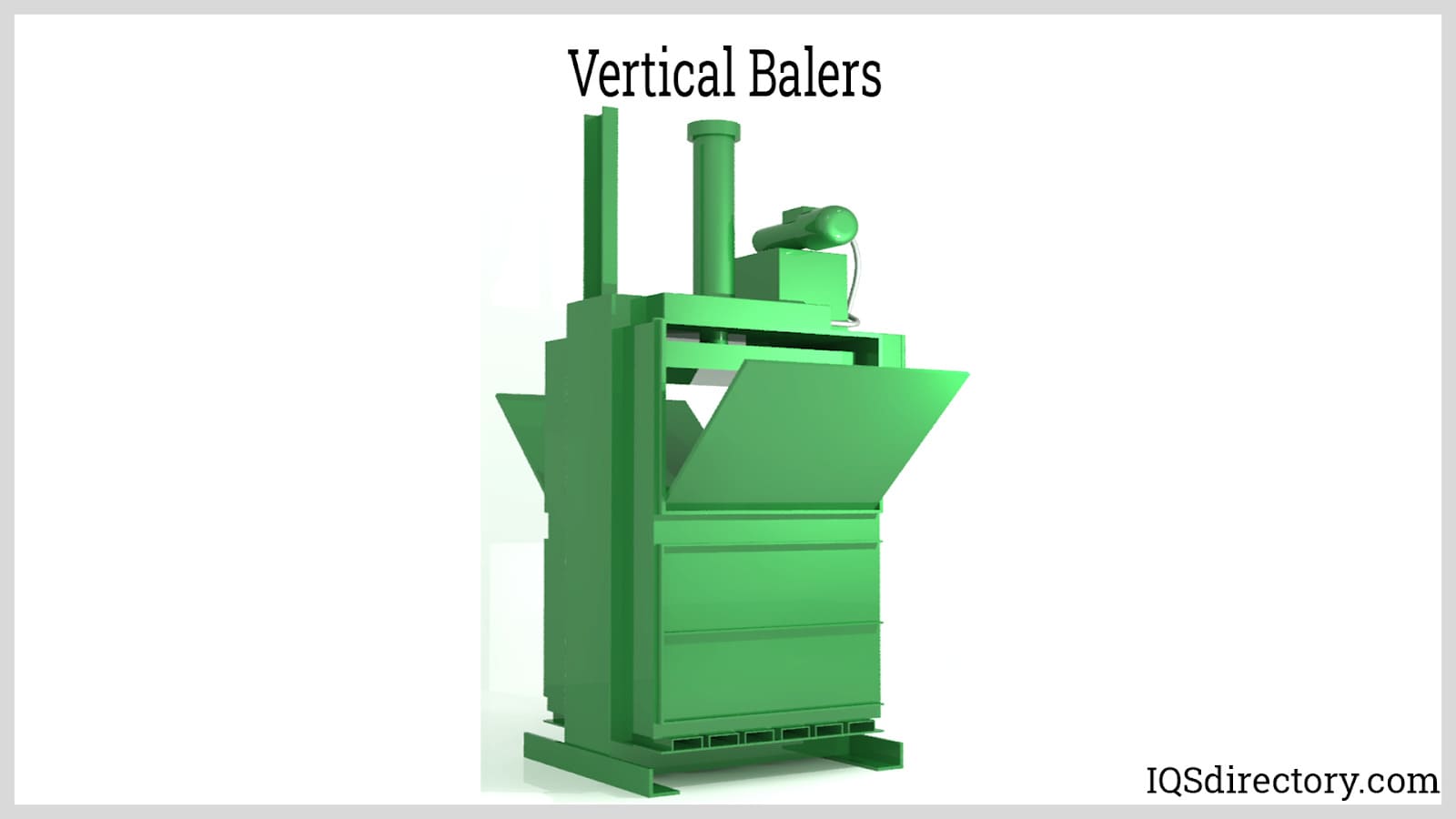

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services