Recycling Equipment

The recycling process starts with material collection. A waste management company gathers recyclables from homes, commercial dumpsters, and industrial facilities using trucks. These materials are then transported to a recovery center for processing. From there, the right combination of recycling equipment—matched to the material stream, throughput, and end-market requirements—turns mixed discards into saleable commodities while minimizing what ends up in landfills.

Repurposing used materials to avoid landfills is essential for reducing environmental impact and conserving resources. An efficient recycling process allows residential, commercial, and industrial locations to dispose of, sort, and reuse materials such as metals, plastics, rubber, construction waste, wood, paper, cardboard, glass, and textiles. When the system is designed correctly, each step supports higher recovery rates, cleaner bale quality, and a circular economy that turns waste into new value.

From Collection to Pre-Processing

Recyclables arrive at a materials recovery facility (MRF) or transfer station either pre-sorted (dual-stream) or mixed together (single-stream). Single-stream collection typically drives higher participation, but it shifts more sorting work to the facility. To prepare inbound loads for efficient separation, operators rely on material handling conveyors, infeed hoppers, and metering devices that regulate flow and limit surges. Stable, consistent feed supports higher line speeds and reduces downtime.

For larger recyclables, size-reduction machines such as industrial shredders, granulators, pulverizers, crushers, and mills break materials into smaller, more manageable pieces. Uniform particle size improves downstream separation, washing, and baling. The right rotor design, knife configuration, and screen selection depend on the feedstock—PET and HDPE containers, polypropylene (PP), LDPE film, corrugated cardboard (OCC), pallets and wood waste, tires, or light metals all require different approaches. Consistency at this stage increases throughput and helps protect sensitive equipment farther down the line.

Separation Technologies That Increase Recovery Rates

While some areas require recyclables to be pre-sorted, many regions now accept unsorted materials to promote participation. Consequently, a range of separation technologies has evolved to deliver efficient, accurate sorting at scale:

- Vibratory feeders and screens stabilize product flow and separate by size and mass, removing fines and routing items to the appropriate line.

- Magnetic separators (over-belt or drum magnets) pull out ferrous metals such as steel cans and stray hardware.

- Eddy current separators eject non-ferrous metals—most notably aluminum used beverage cans (UBCs)—to create a clean, high-value stream.

- Optical sorters using near-infrared (NIR) and color sensors identify resins and fiber grades, then deploy targeted air jets to separate PET, HDPE natural and colored, PP, and paper.

- Air classifiers and ballistic separators split light fractions (film, paper) from heavier objects (glass, metals) based on aerodynamic properties.

- Trommel screens and disc screens separate by geometry and size to balance loading across the line and reduce contamination.

These systems often work in series: a trommel may presort by size, magnets remove ferrous metals, eddy currents recover non-ferrous, and optical sorters fine-tune plastics and fiber grades. Manual quality control (QC) stations remain important for removing contaminants and verifying bale purity, but automation increases consistency, raises capture rates, and lowers operating cost per ton.

In the recycling sector, the term recovery rate denotes the proportion of materials that are effectively recycled and prevented from ending up in landfills. Facilities also monitor capture rate (how much of each targeted material is successfully recovered) and contamination rate (unwanted material remaining in the commodity stream). Incremental gains in these metrics translate directly into better pricing from buyers and lower disposal fees for residuals.

Conditioning, Densification, and Bale Quality

After separation, further processing may be required to prepare materials for reuse. Plastics often move through wash lines and dryers to remove labels and residue before flake is sent to an extruder and pelletizer for manufacturing into post-consumer recycled (PCR) resin. Paper and cardboard are graded, sometimes de-inked, and managed for moisture content. Metals may be sheared or screened to meet mill specifications, while glass is cleaned and crushed into cullet.

The materials are then compressed into manageable bales using a baling machine. Densification is the common denominator across commodity types because it lowers transportation costs and streamlines storage and handling. Baling options include:

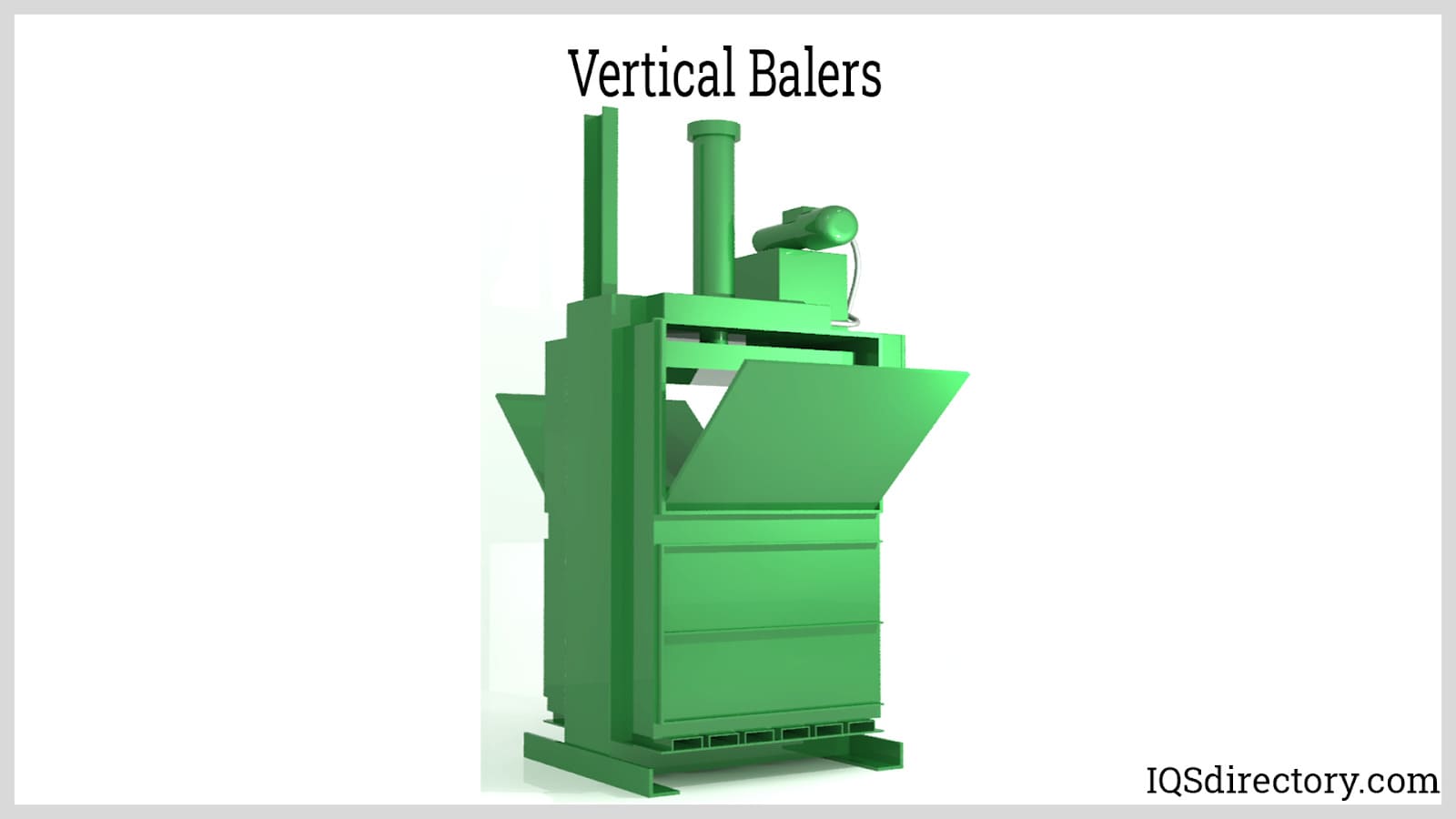

- Vertical balers for lower volumes of OCC, plastics, and textiles—common in retail backrooms and warehouses.

- Horizontal closed-door balers for mid-volume applications that need higher throughput and consistent bale size.

- Auto-tie and two-ram balers for high-throughput MRFs processing multiple commodities and frequent bale changes.

Bale density, dimensions, and tie-wire tension are set to match broker and mill specifications. Consistency reduces breakage, keeps loads within weight limits, and ensures that commodities move quickly to end markets. Many facilities also use compactors, briquetters, and densifiers for specialized streams like foam (EPS), film, or fine metal turnings.

These bales are loaded onto trucks and shipped to factories for reuse in new products. For instance, a bale of crushed metal cans can be transported to a facility where the metal is melted and molded into new cans. Sorted PET may become new bottles or fiber for textiles; cardboard reenters the supply chain as corrugated boxes; and clean glass cullet goes back into containers or fiberglass.

Mixed-Waste Centers and Continuous Improvement

At a mixed-waste center, waste must be separated from recoverable materials. Most facilities can recover approximately 30% of the material today, and the ongoing goal is to increase this percentage through better education, more advanced equipment, and smarter line design. Even small upgrades—adding an optical sorter, refining screen sizes, improving metering—can produce measurable gains in diversion and revenue while lowering landfill tipping fees.

Although some waste is inevitably non-recyclable, enhancing the recovery rate is vital for protecting the environment and conserving resources. Improving inbound quality, expanding commodity outlets, and tuning maintenance programs all support higher capture without sacrificing safety or uptime.

Energy Savings and Emissions Reductions

Creating products from recycled materials requires significantly less energy compared to using raw materials. For example, manufacturing a plastic water bottle from recycled plastic can use up to 88% less energy than producing it from new plastic. Similar savings apply to cardboard, wood, and glass products. Lower energy intensity reduces greenhouse gas emissions and helps organizations meet sustainability targets and reporting requirements.

Recycling equipment selection also influences energy use at the facility level. High-efficiency motors, variable frequency drives (VFDs), and intelligent controls right-size power draw to actual load. Proper conveyor design reduces friction losses, and optimized bale density maximizes truck payload, decreasing the number of trips and associated emissions. When facilities track kWh per ton processed alongside recovery and contamination rates, they gain a clearer picture of true performance.

Safety, Compliance, and Reliability

Reliable recycling operations are built on strong safety practices and code compliance. Guarding, interlocks, and lockout/tagout (LOTO) procedures protect operators around cutters, belts, and rams. Dust collection, spark detection, and fire suppression—particularly near shredders, balers, and storage areas—reduce fire risk and meet insurance and code requirements. Noise abatement, lighting, and ergonomic QC stations support worker well-being, which ties directly to throughput and quality.

Preventive maintenance keeps equipment efficient and extends asset life. Regular knife sharpening and screen changes on shredders and granulators, magnet inspections, belt tracking, and hydraulic fluid checks on balers prevent unplanned downtime. Many modern systems integrate sensors for vibration, temperature, and motor load to enable predictive maintenance and remote diagnostics.

Decision Factors When Evaluating Recycling Equipment

Selecting the right recycling machinery involves balancing capital cost with operating efficiency and end-market demands:

- Material stream and variability. Understand your current mix—OCC, mixed paper, PET/HDPE, PP, film, glass, ferrous and non-ferrous metals, textiles—and consider future growth.

- Throughput and line balance. Size equipment for peak loads measured in tons per hour (TPH). The slowest component dictates overall performance.

- Footprint and layout. Facility dimensions, ceiling height, and traffic patterns affect conveyor angles, mezzanines, and baler placement.

- Energy and consumables. Evaluate electricity usage, compressed air needs, knife wear, tie wire, and parts availability to calculate true total cost of ownership (TCO).

- Automation and data. Controls integration, bale counters, and real-time performance dashboards simplify oversight and support ESG reporting.

- Service and support. Local technicians, stocked spares, and training resources often determine real-world uptime and ROI.

Clarity on these factors helps align equipment choices with program goals—higher diversion, better commodity pricing, or lower operating costs.

Materials and Markets: Where Recycled Content Goes

The value of recycling equipment is realized when recovered commodities meet the specifications of mills and manufacturers:

- Paper and cardboard (OCC, mixed paper). Converted back into boxes, tissue, and other fiber products; moisture and contamination control are key.

- Plastics (PET, HDPE, PP, film). Washed, flaked, and pelletized into PCR resin for packaging, durable goods, and textiles; clear segregation boosts price.

- Metals (ferrous and non-ferrous). Re-melted for cans, sheet, and cast products; magnets and eddy currents improve purity and yield.

- Glass. Clean cullet feeds container and fiberglass manufacturing; size and color separation improve marketability.

- Wood and organics. Processed into mulch, compost, or biomass feedstock where markets exist.

Market demand, transportation costs, and bale quality determine pricing. Facilities that consistently hit buyer specifications move materials faster and capture better margins.

The Bigger Picture: Why It All Matters

Recycling equipment is the engine behind landfill diversion and resource conservation. By pairing effective collection with thoughtful pre-processing, advanced separation, and dependable densification, facilities convert mixed discards into reliable feedstock for new products. Plastics, fiber, metals, glass, wood, rubber, and textiles all find second lives when systems are designed to maximize capture and minimize contamination.

As communities and businesses pursue sustainability targets, recycling delivers measurable results: less waste to landfill, lower energy consumption, and reduced greenhouse gas emissions. Whether the goal is to expand a municipal program, standardize a multi-site commercial recycling effort, or upgrade an industrial line, the path forward is the same—match equipment to the stream, size for throughput, prioritize safety and maintenance, and commit to continuous improvement. With that approach, recycling turns everyday materials into consistent revenue and lasting environmental benefits.

What types of materials can be processed by recycling equipment?

Recycling equipment can process a wide variety of materials including metals, plastics, rubber, construction waste, wood, paper, cardboard, glass, and textiles. The system design is tailored to the specific mix of materials at each facility.

How do materials get sorted at a recycling facility?

Materials are sorted using a combination of technologies such as vibratory feeders, magnetic separators, eddy current separators, optical sorters, air classifiers, trommel screens, and manual quality control stations. These systems separate materials by size, weight, magnetic properties, and optical characteristics to enhance recovery and bale purity.

What is the purpose of baling in the recycling process?

Baling compresses materials into dense, manageable shapes that reduce transportation costs and simplify storage and handling. Different types of balers—vertical, horizontal closed-door, auto-tie, and two-ram—are used depending on volume and material stream. Consistent bale density and size help materials meet market specifications and move quickly to end users.

How does recycling equipment help reduce energy use and emissions?

Using recycled materials to manufacture new products requires much less energy than using raw materials. For example, recycled plastics can reduce energy use by up to 88%. Energy-efficient recycling equipment, such as those with high-efficiency motors and optimized conveyor designs, further lowers facility-level energy use and reduces greenhouse gas emissions.

What are key safety and maintenance considerations for recycling equipment?

Effective recycling operations require guarding, interlocks, lockout/tagout procedures, dust collection, spark detection, fire suppression, noise abatement, and ergonomic workstations for safety and compliance. Regular maintenance, such as knife sharpening and belt tracking, along with predictive diagnostics, helps ensure reliability and minimize downtime.

What factors should be considered when selecting recycling equipment?

Important factors include the material stream and its variability, facility throughput requirements, available space and layout, energy and consumables usage, automation capabilities, and access to service and technical support. Balancing these considerations ensures the investment aligns with program goals such as higher recovery, better pricing, or reduced costs.

Why is improving recovery rate important in recycling centers?

A higher recovery rate means more materials are recycled instead of being sent to landfill, directly benefiting the environment by conserving resources and reducing waste. Improved recovery also increases revenue, reduces disposal fees, and supports sustainability targets for communities and businesses.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services